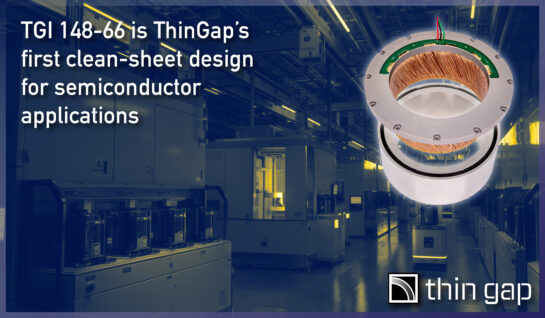

ThinGap is pleased to announce first deliveries of its new TGI 148-66, marking a clean-sheet motor targeted at air-bearing applications within the semiconductor market. The new part set has a rotor diameter (OD) of 148 mm, and an axial height of 66 mm. With a total mass of just over 2.4 kg, it offers a continuous torque output of 10.9 N-m, and peak 1-second torque as high as 80.1 N-m.

The TGI 148-66 highlights the highly flexible architecture of ThinGap’s TG Series. TG Series motors utilize an ironless, toothless stator design, resulting in linear torque constants and exceptionally high peak torque capability for highly dynamic, responsive actuation. The absence of iron eliminates attractive forces between the rotor and stator, a critical advantage in air-bearing applications. When combined with a near-perfect sinusoidal back-EMF and drive, this design effectively eliminates torque ripple while producing zero cogging and zero radial disturbance forces. Together, these characteristics deliver an ultra-high level of precision, smoothness, and responsiveness—key performance advantages for next-generation semiconductor applications seeking improved accuracy and higher processing throughput.

The TG Series has previously been successfully used in a wide variety of generator, propulsion, and flywheel applications, ranging from gyro-stabilization in marine applications and satellites, to airborne starter-generators. Furthermore, the process steps needed to produce motors of all sizes are highly scalable, with the company shipping motors ranging between 25 mm up to 600 mm in diameter.

To learn more about ThinGap’s custom motor capabilities, please contact the company.