With demand for electronics at an all-time high and a global supply shortage, the Semiconductor Equipment industry is busier than ever. Today’s modern wafer processing, automatic test and packaging system have a need for increased force density and high resolution move and hold steps. Highly precise, yet compact designs help enable inline process steps that are critical to higher throughput.

There are many needs for high precision BLDC electric motors in every stage of semiconductor production, from wafer processing all the way to inline testing. Motor selection is critical to system architecture, and factors in control methods, feedback requirements, and mechanical attributes.

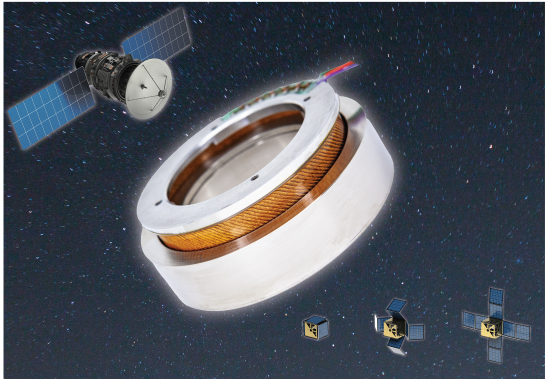

Motors and actuators used for these applications are required to deliver cogless and absolute precision. Low profile motor architecture is ideal, because of the large internal aperture so optics or cabling can be routed through the middle. In addition to wafer positioning, precision motors are needed to direct optical systems, such as beam steering, with precision actuation to deliver precision to the micron level.

The continued use of Direct Drive solutions enables system-level advancements needed by semiconductor processing and test equipment. Rapid and accurate movement defines the performance specifications.

Beyond zero cogging, ThinGap motor kits have near zero Eddy-current, low hysteresis, and a harmonic distortion of less than 1%, so torque output is directly proportional to current throughout the operating range. The resulting smooth motion, linear output, and low profile of ThinGap’s motor kits make them perfect for use in precision applications. Slotless motor kits with high torque, direct-drive capabilities are in many cases the ideal solution for semiconductor equipment.

ThinGap’s LS Series of slotless motor kits is an industry leader for applications requiring performance and efficiency. Standard LS motor kits range in size from 25 to 267 mm diameter and produce torque from 0.1 to 12.0 N-m continuous. With standard and modified configurations, the product line will cover voltages from 24-400 volts and current from 1 to 100 amps.

To learn more about the LS Series, click here.